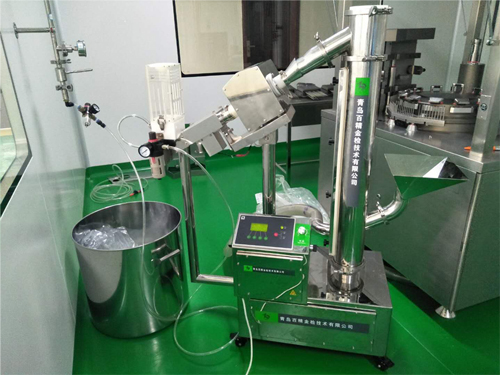

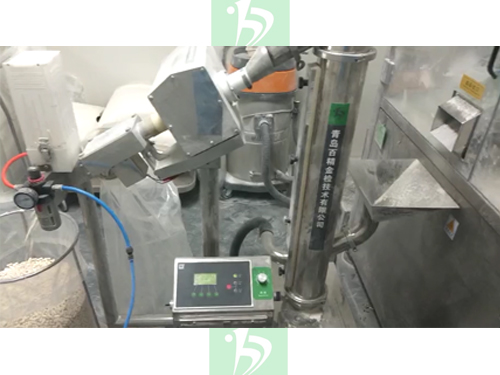

Metal Detector and Capsule Polisher

For capsules de-dusting polishing lifting and sorting of the capsules. metal impurities are separated from capsules as well.

Work Simulation

Product Introduction

Essential Information

Quality: This machine adopts German technology. The polisher adopts spiral principle performance is stable.

Application: Especially to use with capsule filling machine for capsules de-dusting polishing and lifting of the capsules. metal

impurities are separated from capsules as well. Empty broken or separated capsules are sorted automatically.

Site: This machine can use with any model capsule filling machine or use as independent unit.

Application: Especially to use with capsule filling machine for capsules de-dusting polishing and lifting of the capsules. me

impurities are separated from capsules as well. Empty broken or separated capsules are sorted automatically.

Site: This machine can use with any model capsule filling machine or use as independent unit.

Product Advantages/ Performance Characteristics

Design: Open and modular design; the brush the inlet and outlet ports can be dismantled extremely easy for maintenance.

Thoroughly hygienic design. The brush is food grade material. Machine polishing result is good high production

efficiency. Complete separation of dust and machinery.

Height: The machine height can be adjusted to meet requirements.

Appearance: It is made of stainless steel fully mirror polished. Product contact part is SS304 (SS316L is optional). The capsule

sorting unit and non metallic parts are all made of food grade material.

Cleaning: This machine is modular design free tool dismantling easy cleaning safe and compliment with GMP specifications.

System: Inverter technology is adopted can adjust speed and pause user friendly.

Operation: Operation by manual knobs which are intuitive and convenient for operation.

Sorting: Use compressed air

Powder Discharging: It has an exclusive outlet for fine powders. It can connect to a bypass from the capsule filling machine. It can also use

an independent vacuum cleaner.

Power: The whole machine power consumption is 0.3kw/H which is entirely energy saving. Power supply 220V with earthing.

Scheme: The machine is compliment to the requirements of the GMP and CE.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Documentation: All the material certifications as well as IQ OQ PQSOP and FAT are supplied with.

Metal detector: Please refer to Pharmaceutical metal Detector.

Thoroughly hygienic design. The brush is food grade material. Machine polishing result is good high production

efficiency. Complete separation of dust and machinery.

Height: The machine height can be adjusted to meet requirements.

Appearance: It is made of stainless steel fully mirror polished. Product contact part is SS304 (SS316L is optional). The capsule

sorting unit and non me

Cleaning: This machine is modular design free tool dismantling easy cleaning safe and compliment with GMP specifications.

System: Inverter technology is adopted can adjust speed and pause user friendly.

Operation: Operation by manual knobs which are intuitive and convenient for operation.

Sorting: Use compressed air

Powder Discharging: It has an exclusive outlet for fine powders. It can connect to a bypass from the capsule filling machine. It can also use

an independent vacuum cleaner.

Power: The whole machine power consumption is 0.3kw/H which is entirely energy saving. Power supply 220V with earthing.

Scheme: The machine is compliment to the requirements of the GMP and CE.

Levels: Protection Degrees: IP65 which can meet the requirements of HACCP certification.

Documentation: All the material certifications as well as IQ OQ PQSOP and FAT are supplied with.

Me

Special Description

Integrated unit: Control unit is imported from Germany. Capsule polisher and metal detector are integrated design use one control

box to control both machines. Machine is compact structure to suit site environment. Intuitive operation of machines

user password has level control. Machine has performance self qualification function. It has closed product transport

within the unit. Suitable for hazardous products and ensure production safety.

Metal detector: Please refer to 800kHz high precision Pharmaceutical metal Detector.

box to control both machines. Machine is compact structure to suit site environment. Intuitive operation of machines

user password has level control. Machine has performance self qualification function. It has closed product transport

within the unit. Suitable for hazardous products and ensure production safety.

Me

Technical Parameter

| Suitable product | Capsule 00#-4# |

| Dimensions | 1225X475X1405mm ( integrated unit) |

| Capacity | Maximum 300000 PCS/H |

| Discharge time | 5s |

| Surface finish | Good |

| Power | 220V/110V 50/60Hz |

| Integrated unit |

me maximum scanning sensitivity Fe 0.2mm SUS 0.4mm NoFe 0.3mm |

Quality Assurance

Performance: Metal detector and Polisher integrates capsule polishing de-dusting metal impurities separation and empty

capsule sorting functions.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Accept: We accept challenge testing.

Warranty: 12 months.

After-sale: For domestic customers we promise to resolve any issues within 48 hours. And for overseas customers we

promise to send out parts within 12 hours.

capsule sorting functions.

Improve: Always improve the quality of products.

Optimization: Optimize production process and improve efficiency.

Benefits: Leave the unqualified products in your workshop avoid complaints and improve your corporate image.

Accept: We accept challenge testing.

Warranty: 12 months.

After-sale: For domestic customers we promise to resolve any issues within 48 hours. And for overseas customers we

promise to send out parts within 12 hours.